How Thermographic

Imaging enhances the

inspection process

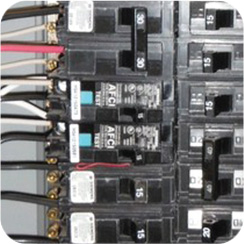

Infrared Thermography is a non-invasive tool used to detect, measure and

take pictures of temperature variations of objects or surfaces. This

information, when interpreted by a trained thermographer, can detect

problems that cannot be seen by the naked eye - problems that could potentially cause damage to the home and its foundation if

left unattended.Infrared cameras cannot see through walls. They can only "see" the heat of an object or surface. It allows the inspector to visualize and document gradients in the temperature of surfaces such as walls and ceilings. It is highly effective in detecting moisture issues (even before they are visible to the naked eye), thermal issues (insulation deficiencies and air leakage) and electrical issues.

In short, a thermographic scan of all the interior surfaces of the home can locate potential problems without the need for any invasive or destructive measures and can save you in potential repair costs.

SCROLL OVER TO VIEW

THERMAL IMAGE

Moisture

Thermographic imaging can detect moisture even before it penetrates the walls, floor coverings or ceilings. It can detect potential water leaks in the basement and throughout the home to determine whether any further waterproofing is required. Untreated moisture issues can lead to mold and damage to surrounding surfaces. The infrared image on the left shows the extent of damage from a leaking bathtub. The dark area displays the amount of moisture beneath the carpet that was not visible to the eye.

SCROLL OVER TO VIEW

THERMAL IMAGE

Insulation

A thermographic scan of the home's surfaces can also help detect potential air leaks and inefficiencies in insulation. Depending on the season, a thermographic scan will detect any potential warm spots (in the warm months) and cool spots (in the cold months). The cool spots in the thermal image on the left reveal a problem with the insulation.

SCROLL OVER TO VIEW

THERMAL IMAGE